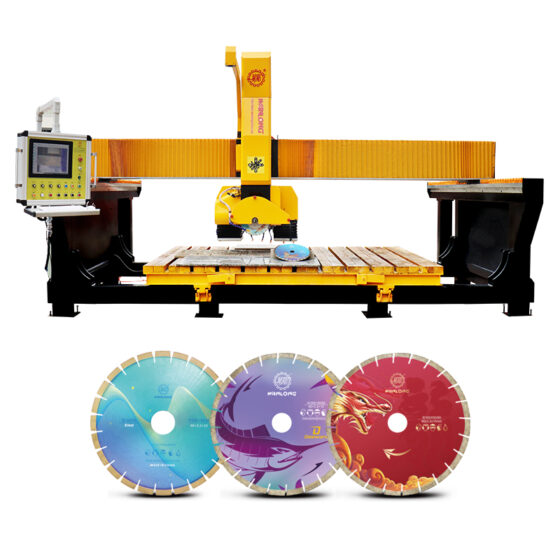

(CNC-5 Pro) 5 Máquina de corte y fresado de puentes CNC Axis

_01.webp)

1. CNC control system, CAD, CAM drawing software and the digital servo motor

2. 4-axis linkage+l-axis electric

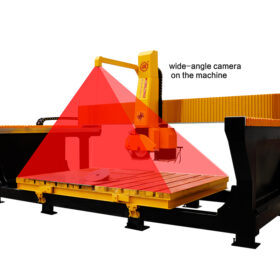

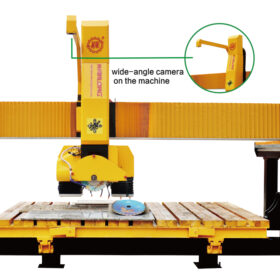

3. Take photos and position, optimize typesetting that improve the material yield, and the suction cup automatically moves the workpiece to optimize the processing

4. Use wide-angle camera that occupy small the space (height)

5. The whole slab image from desktop can be obtained by the camera and positioning at one time, which is intuitive to operate and eliminates manual positioning

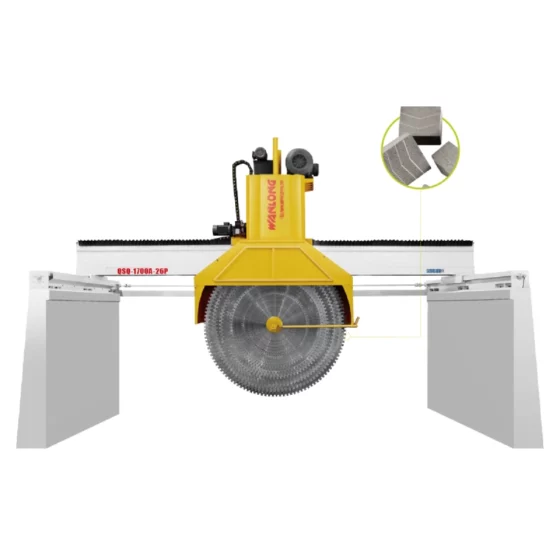

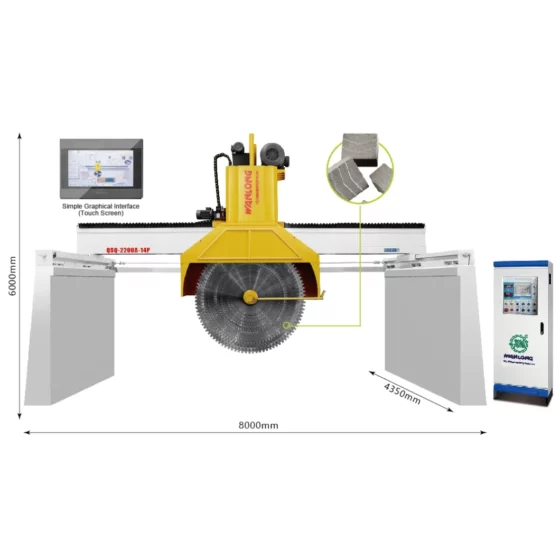

6. to Support the combined processing of saw blade and milling cutter

7. The configured AutoCAD plug-in can directly transfer the graphics to the five axis system in advance, which is easier to operate and supports the import of dxf files

8. The pneumatic control box is external for easy observation and adjustment

9. Linear slide rail and ball screw shall be selected from Taiwan HIWIN brand

10 .Star gear reducer adopts Margtech

11 .The robot reducer adopts Qinchuan brand

12. Pneumatic components shall be Taiwan Yadeke brand

|

Model

|

Unidad

|

CNC-4

|

|

Carrera del eje lineal(X-Y-Z)

|

milímetro

|

3500-2360-330

|

|

Carrera del eje C

|

n°

|

±180

|

|

Un trazo de eje

|

n°

|

-1~91

|

|

Diámetro de la hoja

|

milímetro

|

350-500

|

|

Potencia del motor principal

|

KW

|

18.5

|

|

Rotación nominal del motor principal

|

r/min

|

3600

|

|

Velocidad lineal nominal (X-Y-Z)

|

m/min

|

30-30-5

|

|

Par nominal del motor principal

|

Nm

|

49.1

|

|

Velocidad de rotación nominal del eje C

|

r/min

|

17.3

|

|

Velocidad de rotación nominal del eje A

|

r/min

|

20.66

|

|

vacuum sunker numbers

|

4

|

|

|

Máximo. capacity of vacuum sucker

|

Kg

|

360

|

|

rounter bit connector

|

ER25UM

|

|

|

Table size

|

milímetro

|

3200*2000(3500*2100)

|

|

Total power of machine

|

KW

|

33.2

|

|

Overall size

|

milímetro

|

5850*3380*3050

|

|

Machine Weight

|

Kg

|

4000

|

|

Consumo de agua

|

L/min

|

15-25

|

|

Air consulmption

|

L/min

|

176

|

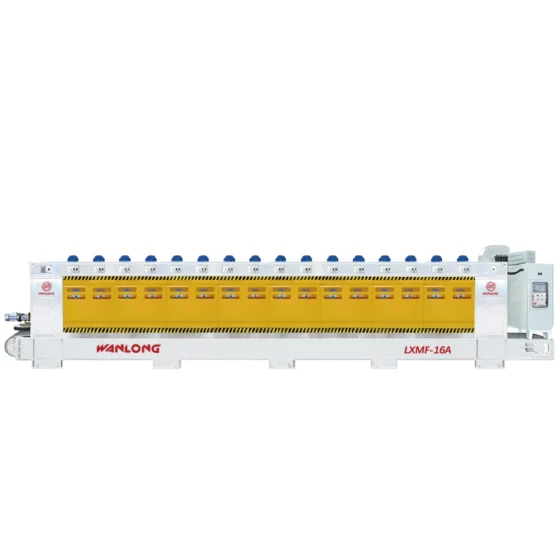

CAJAS DE CORTE

TIEMPOS DE WANLONG

TIEMPOS DE WANLONG