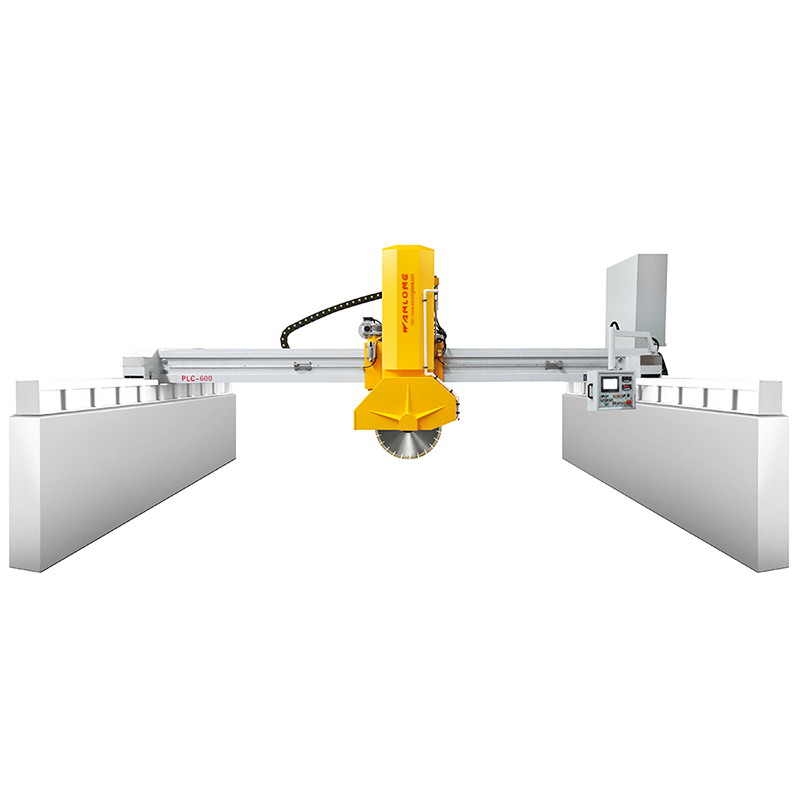

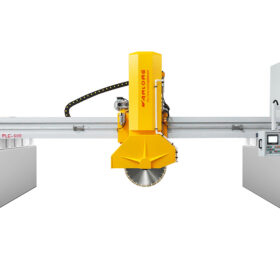

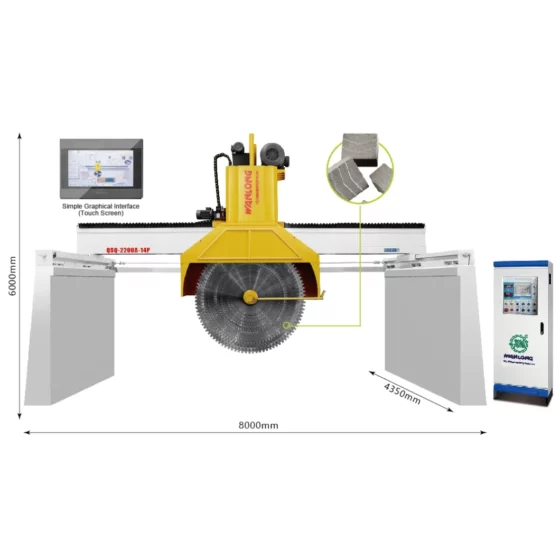

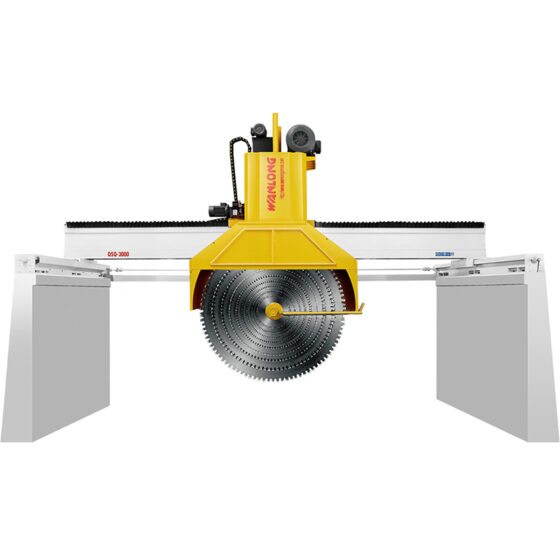

PLC-600/800 laser bridge cutting machine is to cut the slab into required standard size slab accrately. PLC-600/800 series laser bridge cutting machines are quite suitable for high-valued and large size natural stones cutting and processing.

The machine is for slab processing. which adopts PLC Control System, Imported Frequency converter, Precise Signing Laser etc for automatic function and guarantee its precise and stable cutting.There are model PLC 600 and PLC 800 available for your choice.

Stone available to process: granite, marmer, limestone, travertine, basalt, sandstone, soapstone, dll..

_01.webp)

Laser Bridge Cutting Machine Configurations:

* PLC Control System

* Imported Frequency converter

* Precise Singing Laser

* Table tilting degree:0-85°

* Table rotating degree:90-360°

* Max.cutting size:3200*2000*180mm

* PANSONIC PLC

* PANSONIC inverter

| Pola | Satuan | PLC-600 | PLC-800 |

|---|---|---|---|

| Maks. diameter of blade | mm | 350-600 | 500-800 |

| Daya motor utama | KW | 15(18.5) | 22 |

| Main motor with inveter | Optional | Optional | |

| Table dimensions(L x W) | mm | 3200*2000 | 3200*2000 |

| Table tilting degree | n° | 0-85° | 0-85° |

| Table rotating degree | n° | 90°-360° | 90°-360° |

| Maks. cutting size(L x W x H) | mm | 3200*2000*180 | 3200*2000*280 |

| Dimensi keseluruhan(L x W x H) | mm | 6000*4500*3000 | 6000*4500*3200 |

| Konsumsi air | m³/jam | 4 | 4 |

| Perkiraan berat | Kg | 4800 | 5000 |

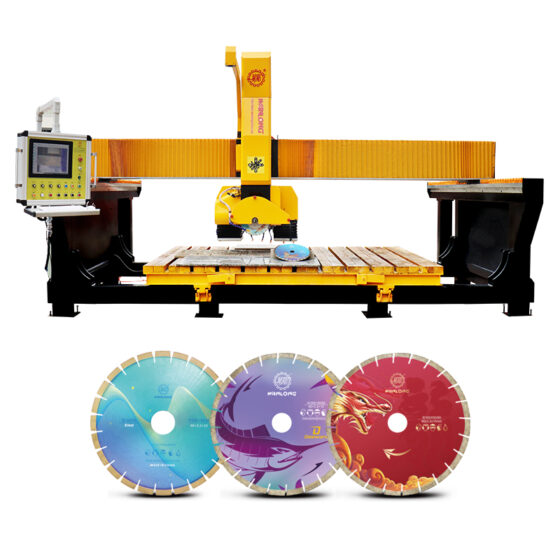

Laser Bridge Cutting Machine Features:

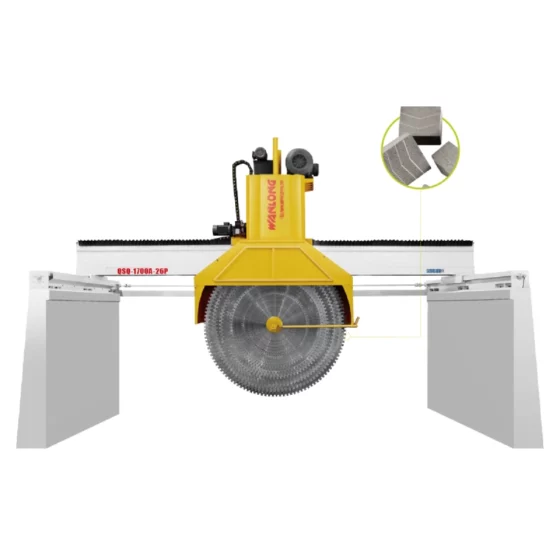

1. The blade can be tilted 45°and chamfer the edge.

2. Bridge structure with wide crossbeam, large size of slab cutting available.

3. Equipped with infrared device, precise cutting location reachable.

4. Desain trek geser yang tahan debu memastikan gerakan pemandu yang tepat & umur panjang

5. PLC control system, programmable, fully automatic & smooth cutting

6. Precise movement of head in X, Y, Z directions by rack & gigi

7. Electric parts of Japanese famous brand adopted, reliability guaranteed

8. Touch-sensitive operating system, friendly human-machine interface

9. Worktable can be automatically rotated 90°or 360°, flip 85°,which make loading/unloading and changing the cutting direction easier.

_03.webp)

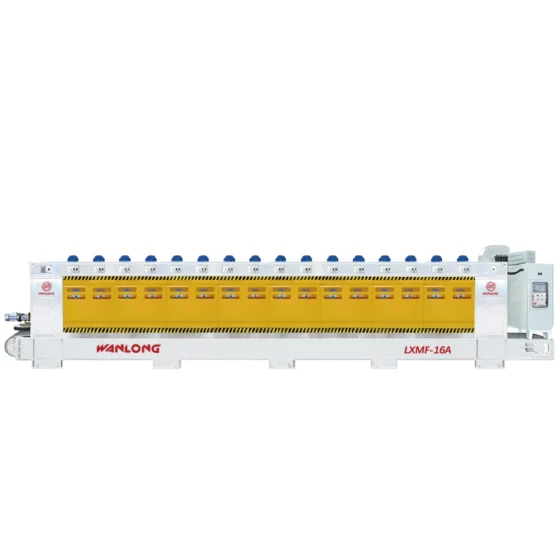

WAKTU WANLONG

WAKTU WANLONG