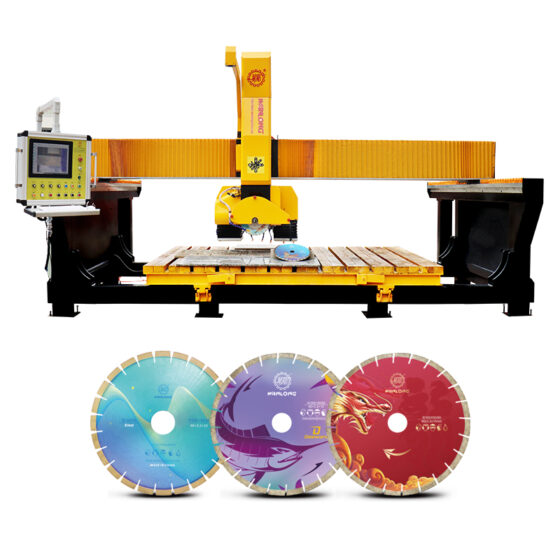

The machine is under computerized control, under the touch operating interface, and is equipped with wireless remote control, enabling the man-machine dialogue to be flexible and free. The main control components all use intermational famous brand components, cross frame oil diffuse type double V track, transverse knife adopts stepless frequency conversion speed regulation, longitudinal spliter adopts linear guide rail and high precision magnetic ruler count, to ensure the machine work stable and stable precision. The integration of fuselage and workbench base not only facilitates the installation and transportation of users, but also ensures the stability of the machine.

|

Model

|

Jednostka

|

CNC-4

|

|

Liniowy skok osi(X-Y-Z)

|

mm

|

3500-2360-330

|

|

Skok osi C

|

nr

|

±180 szt.

|

|

Skok osi

|

nr

|

-1~91 pkt.

|

|

Średnica ostrza

|

mm

|

350-500

|

|

Moc silnika głównego

|

KW

|

18.5

|

|

Znamionowe obroty silnika głównego

|

obr/min

|

3600

|

|

Znamionowa prędkość liniowa (X-Y-Z)

|

m/min

|

30-30-5

|

|

Znamionowy moment obrotowy silnika głównego

|

Nm

|

49.1

|

|

Znamionowa prędkość obrotowa osi C

|

obr/min

|

17.3

|

|

Znamionowa prędkość obrotowa osi

|

obr/min

|

20.66

|

|

Wielkość załadunku

|

mm

|

5675*2250*2250

|

|

Rozmiar stołu roboczego

|

mm

|

3200*2000(3200*2100)

|

|

Moc silnika głównego

|

KW

|

27.7

|

|

Wymiary

|

mm

|

5675*3380*3050

|

|

Ciężar

|

Kg

|

3800

|

|

Zużycie wody

|

l/min

|

15-25

|

1 Ekran dotykowy PLC, Układ sterowania Beckhoff, Łatwy w obsłudze.

2 Oś Y przyjmuje formę podwójnego napędu, który jest łatwy do regulacji belki poprzecznej i zapewnia płynną i dokładną pracę.

3 Części łączące skrzynię biegów przyjmują połączenie bezluzowe, aby zapewnić dokładność i stabilność pracy.

4 Automatyczne fazowanie cięcia, automatyczne cięcie w pionie i poziomie za pomocą jednego przycisku.

5 Służy do cięcia w linii prostej i łuku.

The machine has a total of 4axis: X axis ~ horizontal movement, Y axis ~ vertical movement, Z axis ~ lift, C axis ~ horizontal rotation of the machine head 0-360?, the four axes can be operated in linkage. The fifth axis, that is, the A axis, is vertically flipped at 0 to 90?, which is used for stone chamfering or three-dimensional bevel cutting.

smooth any angle movement.

X: crosswise movement,

Y:lengthways movement,

Z:lifting,

C:cutter 360 horizontal rotation,

A: Cutter 90 vertical titling.

In this way, our 4-Axis CNC Bridge Cutting Machine can cut any degree to reach any place within cutting area, which output all kinds of shapes with optional size like below which are are our current Main shapes:

This 4-Axis CNC Bridge Cutting Machine hangs a 350-500 diameter saw blade, the main motor is 18.5KW, and is equipped with a 22KW inverter, the rated speed is 3600r/min, and the thickness of the cut stone can be up to 140mm. Due to the frequency conversion speed regulation, it can process building materials of various hardness. Such as various hardness of granite, marmur, artificial granite, slate and ceramic tiles. According to the hardness and characteristics of various materials, the optimal cutting line speed can be adjusted to obtain the maximum work efficiency.

for Marble: RPM 2300,speed at 2-3m/min

for Granite: RPM2100, speed at 7-9m/min

for dekton: Dekton cutting,RPM 2400, speed at 3-3.5m/min

for Ceramic : RPM2600, speed at 3-4m/min

Because the X, Y, Z, C four axes of the machine can run in linkage, it can automatically saw and cut stones with various plane patterns. Such as specification boards, arbitrary straight lines, parallelograms, grids, stove tops, triangles, regular polygons, trapezoids, circles (external and internal circles), ovals, sectors, positive and negative chamfers, horse belly edges and profiling, etc.

This 4-Axis CNC Bridge Cutting Machine marble with very good speed and clean edge also is a good bridge cutting machine for granite, dekton , porceline ..etc.

Marble

Granite

Dekton

Ceramic

CZASY WANLONG

CZASY WANLONG