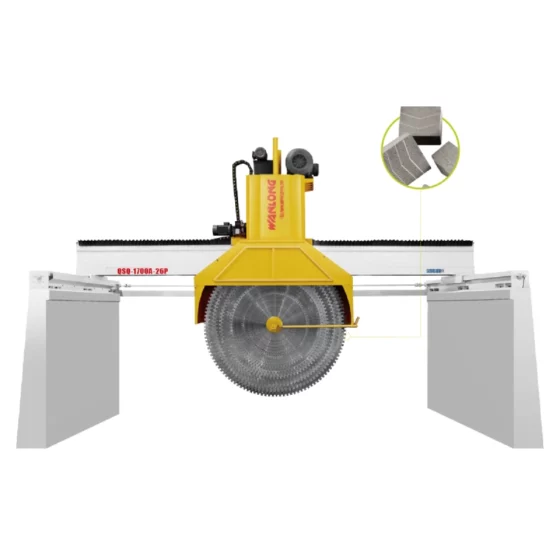

There are 4 main Double-blades-Combinations:

D2200/D3300, D2200/D3600, D2400/D3300, D2400/D3600

| Blank thickness (MM) |

Blanks Diameter (MM) |

Blanks tips (PCS) |

Segment Size (MM) |

| 9.5/10.0 | 2200 | 132 | 23*14/13*15 |

| 9.5/10.0 | 2400 | 136 | 23*14/13*15 |

| 9.5/10.0 | 3300 | 170 | 23*12.5/11.5*15 |

| 9.5/10.0 | 3600 | 180 | 23*12.5/11.5*15 |

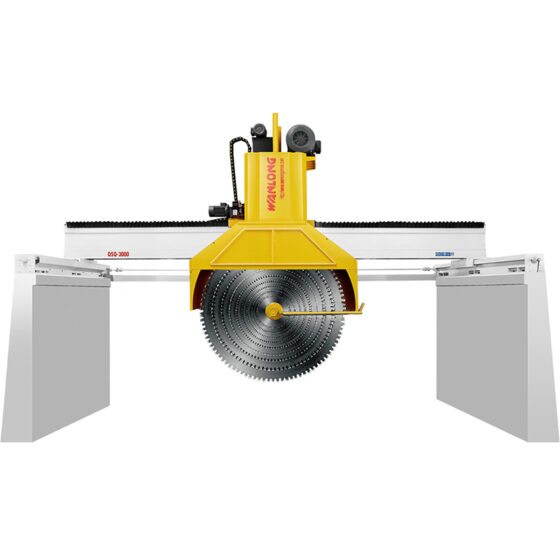

There are 3 main Triple -Blade-Combinations:

D2600/D3600/D4200,D2600/D3800/D4600, D2600/D3800/D4800

| Blank thickness (MM) |

Blanks Diameter (MM) |

Blanks tips (PCS) |

Segment Size (MM) |

| 12 | 2600 | 142 | 23*16/15*15 |

| 12 | 3600 | 180 | 23*15/14*15 |

| 12 | 4200 | 210 | 23*14/13*15 |

| Blank thickness (MM) |

Blanks Diameter (MM) |

Blanks tips (PCS) |

Segment Size (MM) |

| 12 | 2600 | 154 | 23*16/15*15 |

| 12 | 3800 | 190 | 23*15/14*15 |

| 12 | 4600 | 230 | 23*14/13*15 |

| Blank thickness (MM) |

Blanks Diameter (MM) |

Blanks tips (PCS) |

Segment Size (MM) |

| 12 | 2600 | 180 | 23*16/15*15 |

| 12 | 3800 | 190 | 23*15/14*15 |

| 12 | 4800 | 240 | 23*14/13*15 |

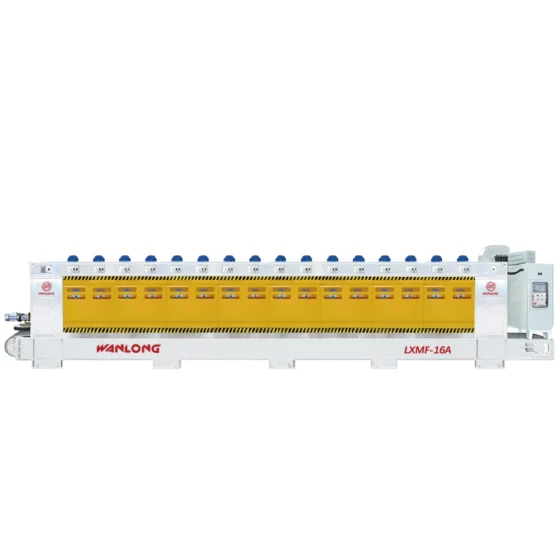

Performance of Stone Quarrying Segments

Quarrying Segment is suitable for granite, marble basalt, slate, sandstone quarrying. It is quite famous by the quarrying workers, thanks to its speedy, deep and long life cutting.

| Material To Cut | Stone Hardness | Feeding Speed | Lifespan (M) | Blade Combination | |||

| (CM) | 0-70 Stroke | 0-110 Stroke |

Smaller Blade | Bigger Blade |

|||

| G.天岗白 | Hard | 12 | 20-25 | 45-50 | 400 | 450 | D2400/D3300 |

| G.623 | Meium Hard | 12-15 | 30 | 60-75 | 550 | 950 | D2400/D3300 |

| G.654 | Soft | 20 | 30 | 70-80 | 1000 | 1300 | D2400/D3300 |

Advantage of Quarrying Segments

1. Good Sharpness: speedy cutting, low current of the machine, mining blocks are square with good flat surface

2. Long Life: Reducing the times of blanks re-welding, maximizing the lifespan of steelblanks, achieving high cutting linear meters and eventually saving the mining cost for the quarry mining owners.

3. Good Adaptability: Suitable for different stone and various complicated mining environments.

ВРЕМЕНА ВАНЬЛУН

ВРЕМЕНА ВАНЬЛУН